Data Sheets + Resources

At Rea Magnet Wire, we understand that access to accurate information is essential for making informed decisions about your magnet wire solutions. That’s why we offer a comprehensive collection of product data sheets designed to provide detailed specifications and insights into our extensive range of magnet wire products.

These resources not only showcase our commitment to quality and performance but also include helpful tools like a conversion chart to assist you in selecting the right wire for your applications. Whether you’re an engineer, manufacturer, or designer, our data sheets serve as a valuable resource to help you navigate your options and ensure optimal results for your projects.

Explore our data sheets below to learn more about our premium magnet wire offerings and how they can meet your unique needs.

Technical Data

Packaging Data

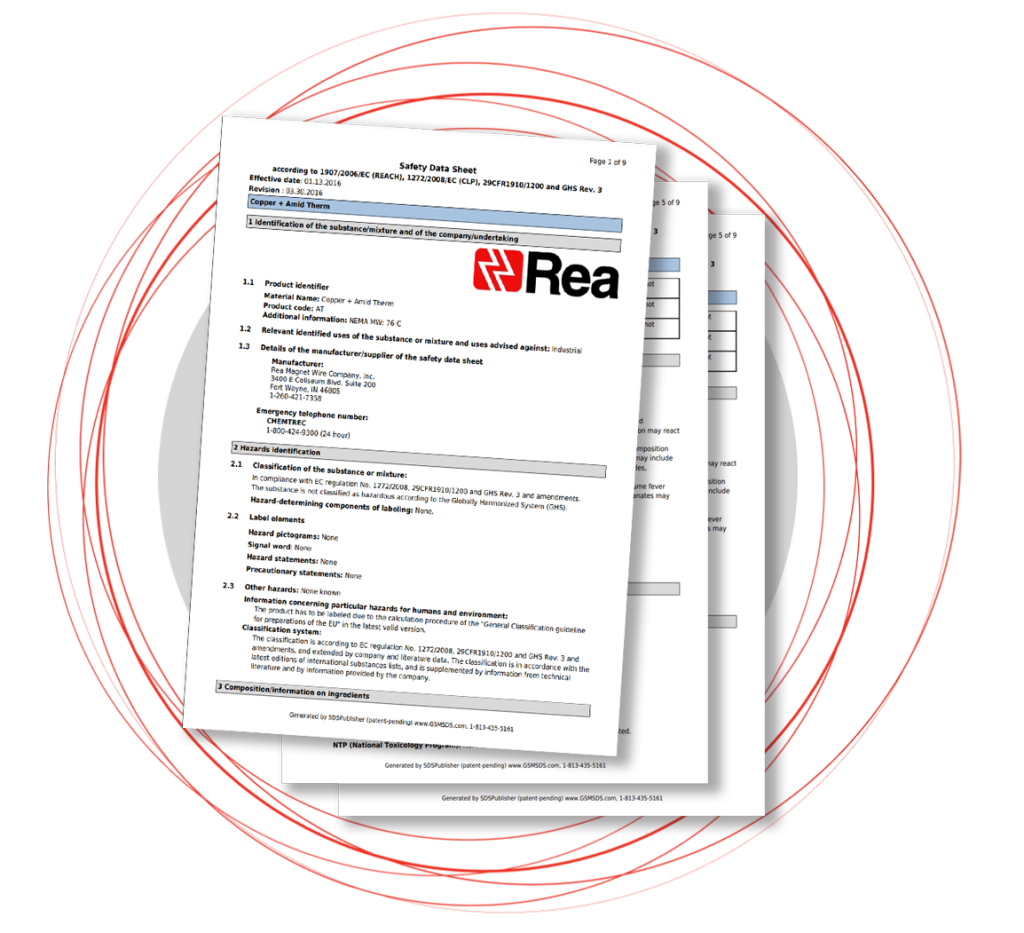

Safety Data

Aluminum Products

- 8176 Aluminum Alloy Bare WireBare

- Aluminum + Amid ThermAmid Therm

- Aluminum + FormvarFormvar

- Aluminum + MagneflexMagneflex

- Aluminum + Nysol (155)Nysol (155)

- Aluminum + Reabond S Therm-AimidReabond S Therm-Aimid

- Aluminum + Reabond S Therm-IDReabond S Therm-ID

- Aluminum + Therm-Aimid, HyslikTherm-Aimid, Hyslik

- Aluminum Bare WireBare

- Nomex Wrapped AlNomex Tape

- Paper Wrapped AlPaper Tape

Copper Products

- Copper + Amid ThermAmid Therm

- Copper + Apical KaptonApical Kapton

- Copper + Daglas Bare + Epoxy VarnishCopper + Daglas Bare + Epoxy Varnish

- Copper + Daglas Bare + Polyester VarnishDaglas Bare + Polyester Varnish

- Copper + Daglas Bare + Silicone VarnishDaglas Bare + Silicone Varnish

- Copper + Daglas Bare UnvarnishedDaglas Bare Unvarnished

- Copper + Formvar + Epoxy BondFormvar + Epoxy Bond

- Copper + FormvarFormvar

- Copper + Glass Bare + Polyester VarnishGlass Bare + Polyester Varnish

- Copper + Glass Bare + EpoxyGlass Bare + Epoxy Varnish

- Copper + Glass Bare + Silicone VarnishGlass Bare + Silicone Varnish

- Copper + Linearly Served PaperLinearly Served Paper

- Copper + ML Glass + SiliconeML Glass + Silicone

- Copper + ML Daglas + Epoxy VarnishML Daglas + Epoxy Varnish

- Copper + ML Daglas + Polyester VarnishML Daglas + Polyester Varnish

- Copper + ML Daglas + SiliconeML Daglas + Silicone

- Copper + ML Daglas UnvarnishedML Daglas Unvarnished

- Copper + ML Glass + Epoxy VarnishML Glass + Epoxy Varnish

- Copper + ML Glass + Polyester VarnishML Glass + Polyester Varnish

- Copper + NanoshieldNanoshield

- Copper + Nysol (155)Nysol (155)

- Copper + Pulseshield SDPulseshield SD

- Copper + Pyre MLPyre ML

- Copper + Reabond A NysolReabond A Nysol

- Copper + Reabond A SolvarReabond A Solvar

- Copper + Reabond S Therm-AimidReabond S Therm-Aimid

- Copper + Reabond S Therm-IDReabond S Therm-ID

- Copper + ReaimidReaimid

- Copper + Solvar (155)Solvar (155)

- Copper + TAI Daglas + Epoxy VarnishTAI Daglas + Epoxy Varnish

- Copper + TAI Daglas + Polyester VarnishTAI Daglas + Polyester Varnish

- Copper +TAI Daglas + Silicone VarnishTAI Daglas + Silicone Varnish

- Copper +TAI Daglas UnvarnishedTAI Daglas Unvarnished

- Copper +Therm-Aimid, HyslikTherm-Aimid, Hyslik

- ETP CopperBare

- Nomex Wrapped CuNomex Tape

- Oxygen Free CopperBare

- Paper Wrapped CuPaper Tape

Environmental and Compliance Declarations

Support + FAQ

For personalized assistance, don’t hesitate to get a quote tailored to your needs or explore our FAQ section for quick answers to common questions.

Get A Quote Link

Get a Quote

Quickly request a customized quote for the magnet wire solutions tailored to your project.

FAQ Link

FAQ

Find answers to common questions and learn more about our magnet wires and products in our FAQ section.